- Home

- Committees

- Staff

- Directors

- Calendar

- Asphalt Facts

- Training

- Paving Awards

- AAPA Links

- Membership Directory

- Contact Us

- AAPA Publications & Design Programs

- 2026 35th Annual Asphalt Pavement Association Conference Registration

- 2025 Asphalt Pavement Conference Presentations

- Asphalt Pavement Design Guide for Low Volume Roads and Parking Lots

- Perpetual Pavement Awards

- Great work by Morris King (Vulcan Materials) and Millie promoting Work Zone Safety

- Perpetual Pavement Information

- AAPA Membership Application

- 2026 AAPA 35th Annual Pavement Conference Brochure

Asphalt Facts

Questions & Answers

Below are answers to commonly asked questions pertaining to Hot mix asphalt (HMA). We hope that you will take time to see why HMA is the best and most versatile paving material in the world.

Q: What is Hot Mix Asphalt (HMA)?

A: Hot Mix Asphalt is a combination of approximately 95% stone, sand, or gravel bound together by asphalt binder, a product of crude oil.

Q: How is HMA made?

A: HMA pavement refers to any paved road surfaced with asphalt.

The asphalt binder is heated, combined, and mixed with the aggregate at a HMA facility.

The asphalt binder is heated, combined, and mixed with the aggregate at a HMA facility.

HMA is loaded into trucks for transport to the paving site. The trucks dump the HMA into hoppers located at the front of paving machines. The asphalt is placed, then compacted using a heavy roller which is driven over the asphalt. Because the temperature of the HMA drops rapidly after spreading and because compaction of the HMA to achieve a specified density must take place at temperatures above 175 degrees Fahrenheit, compaction usually takes place within a matter of minutes after the paver spreads the HMA.

HMA is loaded into trucks for transport to the paving site. The trucks dump the HMA into hoppers located at the front of paving machines. The asphalt is placed, then compacted using a heavy roller which is driven over the asphalt. Because the temperature of the HMA drops rapidly after spreading and because compaction of the HMA to achieve a specified density must take place at temperatures above 175 degrees Fahrenheit, compaction usually takes place within a matter of minutes after the paver spreads the HMA.

Traffic is generally permitted on the pavement immediately following compaction.

Q: What are the benefits of HMA pavements?

A: User Benefits

HMA is really the only paving material for our roads that really makes sense. It is the best buy for taxpayers. It is safe, economical, and it is the most long-lasting and durable paving material. In addition, asphalt pavement is 100% recyclable (i.e., old HMA pavements can be remixed with a portion of fresh materials, and used again and again).

HMA also makes sense because it is the paving material of choice on roads in this country. Of the 2.27 million miles of paved road in the US, 94% is surfaced with asphalt, including 65% of the interstate system. In Alabama, approximately 98% (and increasing) of all paved roads are surfaced with asphalt.

HMA pavements provide the user with a smooth, quiet, skid-resistant ride surface. A smooth pavement maximizes tire contact, providing more traction, and saves wear and tear on vehicles.

Economic/Engineering Benefits

HMA pavements can be built very quickly, thereby reducing costs due to traffic delays, which save the traveling public time and money.

Asphalt pavements save taxpayers dollars. In a 3-year analysis conducted by the Florida Department of Transportation, initial construction of an asphalt pavement cost $544,981 to concrete’s $765,729. After wear and tear and maintenance, the residual value of the asphalt pavement was 203% more than the concrete road.

While each road needs to be analyzed based on its own merits, for maintaining roads, the Florida Department of Transportation calculated their routine annual maintenance costs as $132 per lane mile for asphalt pavement and $261 per lane mile for concrete pavement.

HMA gives the best return on investment of any paving material. HMA pavements can be cold milled and recycled which saves costly readjustment of manholes, curbs and sewer drains when rehabilitating urban streets.

Simply put, HMA pavements are the most cost effective pavements in the World, PERIOD!

Environmental Benefits

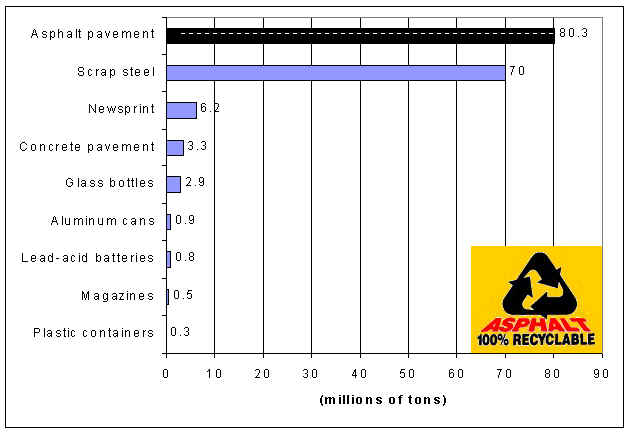

HMA pavements are 100 percent recyclable and are America’s most recycled product. Approximately 80 million tons of HMA are recycled each year. Compare this to other recycled products below. HMA pavements are truly environmentally friendly.

HMA pavement recycling is more cost effective than using only virgin or new materials. The quality of a recycled asphalt pavement is as good as, or even better than, brand new pavement.

HMA pavement recycling not only conserves our precious natural resources and speeds construction, it also saves American taxpayers over $300 million a year.

HMA pavement recycling not only conserves our precious natural resources and speeds construction, it also saves American taxpayers over $300 million a year.

HMA pavements which are not recycled must be disposed of, usually in a landfill. Transporting old asphalt pavements to landfills does not make best use of a product that can be recycled. HMA pavements can be recycled numerous times.

Q: What is the HMA Construction Industry anyway?

A: The HMA Construction Industry is comprised of construction companies producing and placing HMA on roads, airports, parking lots, etc.

There are many different types of HMA companies, ranging from small paving operations to facilities that produce HMA, the premier paving product. The Hot Mix Asphalt Industry directly employs about 300,000 people. Another 600,000 jobs revolve around the HMA Industry: equipment manufacturers, state and local personnel, Asphalt binder suppliers, aggregate suppliers, consulting engineers, etc.

While HMA roads have provided smooth, safe travel for American motorists for most of the century, the industry and the art of building asphalt pavements has gained much sophistication. The industry is very progressive.

The industry has a commitment to quality and continuous improvement.

— Through the National Asphalt Pavement Association’s Research and Education Foundation and Auburn University, the industry has established the National Center for Asphalt Technology (NCAT), where research projects related to asphalt technology are conducted in an academic setting. NCAT has also produced a textbook on asphalt technology and conducts an annual Professor Training Program which teaches courses in asphalt technology to university educators from across the country.

— We have created a scholarship program to encourage the best and brightest young men and women to choose careers in the asphalt industry. These scholarships are available to students. Also, prime scholarship candidates include employees of Hot Mix Asphalt companies who are going to school and are interested in a technical asphalt education.

— The paver modification effort was started because a contractor wanted better conditions for his workers. Now, we are very close to having equipment that removes paving workers from exposure to asphalt fumes on the job site.

— Many of our Members are advocates of Total Quality Management. They work hard to ensure that the product they produce is of high quality and that workers have the equipment and authority they need to do their best work and produce and place pavements of consistently high quality.

— As challenges arise, our engineers create new mixes.

For example, new mixes such as Stone Matrix Asphalt and Superpave have been developed for heavy traffic, high performance pavements.

— We save taxpayers $300 million a year by recycling asphalt pavements. Recycling: the asphalt industry pioneered recycling before it became a buzz word and without legislation encouraging or requiring it.

— As concrete pavements began to wear out and the high costs of rehabilitating them became known, we perfected techniques for rubblizing concrete pavements then overlaying them with asphalt, a substance far more economical and equally long-lasting.

— We are actively involved with state and national agency representatives to ensure appropriate implementation of products from the $50 million Strategic Highway Research Program. The knowledge gained from SHRP research will provide long-term benefits to the HMA Industry.

Q: Are HMA pavements safe?

A: Safety is largely a function of maintaining tire contact with the pavement surface and skid resistance of the surfacing. Smooth HMA roads have superior road contact and high skid resistance.

HMA pavements have distinct advantages over other paving materials when driving in inclement weather.

HMA pavements are impervious to de-icing salts and chemicals and are unaffected by winter road safety maintenance.

HMA pavements can be designed so that water drains through the surface layer of the pavement, thus reducing splash and tire spray and increasing tire-road contact during wet weather. These mixes are called Open-Graded Friction Courses and have now become the standard wearing surface for Alabama’s interstate highway.

HMA pavements retain heat better than other materials so ice doesn’t form as quickly and melts faster.

Q: Is asphalt an environmentally sound product?

A: Yes, asphalt is basically an inert material which is not soluble or harmful in a water environment.

Environmental Liners

Asphalt paving materials have been used to line the surfaces of everything from fish hatcheries to industrial retention ponds. In the case of fish hatcheries, an inert material was needed that would not chemically react with the water. This allows fish and game experts to precisely monitor and control the environment during the delicate stages of incubation and early growth for various fish species.

— For example, Oregon and Washington state fish and wildlife agencies began using HMA to line their fish rearing ponds in 1987. Typically 1/2-acre in area, the ponds are home to chinook salmon and other fry for about 18 months before the fish are released into rivers and streams. Both the Washington and Oregon state agencies are pleased with the effectiveness of the HMA liners and plan to use them for additional fish hatcheries in the future.

For decades, asphalt paving materials have been used as liners for water reservoirs.

— For example, The Metropolitan Water District of Southern California (MWDSC) has been using HMA-lined water reservoirs for more than four decades. Currently, the California Water Resources Board is completing construction on the Devil’s Canyon Reservoir to store MWDSC drinking water. The 19-inch thick asphalt liner for the huge facility will hold 800-acre-feet of water. The East Bay Municipal Utility District (EBMUD) in Oakland, California, has also been using HMA to line domestic water supply reservoirs since the 1950s. A total of ten reservoirs store water in the EBMUD system.

Asphalt binders have also been used to line water pipes that supply potable water to humans.

When used for industrial retention ponds, the inertness of asphalt paving materials keeps liquid industrial waste material from percolating into the soil. This gives industry time to treat the liquid waste, and if needed, provides a platform with which to bring in mobile equipment to move the material to a processing location.

The ability of asphalt paving materials to be both chemically inert and strong enough to provide a structure for heavy equipment accounts for its use as both a landfill liner and cap. In landfills lined with asphalt paving materials, modified earthmoving equipment can be employed to organize and compact landfill waste without fear of breaking the impermeable shell between the solid waste material and the soil.

Clean fill

Many states have tested discarded asphalt pavement and determined that it should be categorized as clean fill.

Even the Environmental Protection Agency’s Toxicity Characteristics Leaching Procedure (TCLP) test, their most extreme and rigorous test for determining the toxicity of a substance, failed to show any appreciable quantities of toxic materials from asphalt pavement material.

Recreational Uses

HMA pavements are a perfect fit for the recreational industry. For years HMA has been used to pave running tracks, bicycle and golf cart paths, in addition to its traditional use for basketball and tennis courts.

Recently, there has been a move in the recreation marketplace to combine exercise with nature. Throughout the country, old nature paths and abandoned rail lines are being converted into thoroughfares for bicyclists, roller skaters, roller bladers, and the occasional pedestrian who wants to view nature while he or she exercises.

Asphalt pavements provide a safe and durable surface with which to accommodate both wheeled and foot traffic.

Other Uses

HMA is also used to pave cattle feed lots, poultry house floors, barn floors, and greenhouse floors. Asphalt not only provides an all-weather platform but also provides protection against disease from waste materials. Asphalt is easy to clean and prevents pollution from getting into water supplies.

Asphalt mixtures are also used in sea walls, dikes, and groins to control beach erosion. Its strength, waterproofing capability, and inertness to sea water help prevent the eroding action of tides and waves.